What Is The Minimum Line Width You Should Use On Screen Printing Spot Color On Tee Shirt

Choosing Your Screen Mesh Count

General Tip: Lower Mesh = More than ink, less item // Higher Mesh = More than detail, less ink

- 60-ninety Mesh - Almost commonly used for thick specialty plastisol inks, such every bit metallics, shimmers, reflectives, puffs, etc.

- 110 Mesh - Most common mesh count for printing with white plastisol ink. Not recommended for water base of operations inks.

- 160 Mesh - Our most popular mesh count. Works well with a wide multifariousness of ink types and substrates.

- 200-230 Mesh - Most commonly used for high detail artwork. Too great for printing with water based inks on woods or newspaper.

- 280-305 Mesh - Used for super fine detail artwork, half tones, CMYK process press, also as solvent and water base of operations inks.

1. What kind of ink are you using?

Many people pick their mesh count solely based off the amount of detail in their artwork, only this is wrong. Information technology is more important to first consider the type of ink y'all are using, since all inks accept very different viscosities. White plastisol ink for example is very thick, so y'all demand a more open mesh count to allow the ink to laissez passer through. On the reverse, black water based ink is extremely thin and needs to go through a finer mesh screen to prevent the ink from bleeding.

2. What cloth are you printing on?

Dissimilar materials absorb different amounts of ink, then different mesh counts should be used to accomplish best print results. Fleece, for example, tends to soak up a lot of ink, so a lower mesh count like 110 or 160 is oft used to allow for better ink coverage. On the flip side, newspaper is non very porous at all, and then yous desire to print a very sparse layer of ink to forbid the ink from bleeding. For paper, you ordinarily want to utilise a minimum mesh count of 200.

3. How detailed is your artwork?

Now that you lot've considered the type of ink you will be using and the material you lot are printing on, it is time to consider the artwork item. If for example you are printing with white plastisol (thick viscosity) on blackness cotton shirts (medium absorbency), yous'll likely exist looking at a range of mesh counts from 110-230. If your artwork is non very detailed and has big blocky portions, y'all should probably stay on the lower side of this range, and then 110. If your artwork is very detailed and consists of a lot of fine lines and modest text, yous should be on the higher side of this range, so 230.

General Guidelines

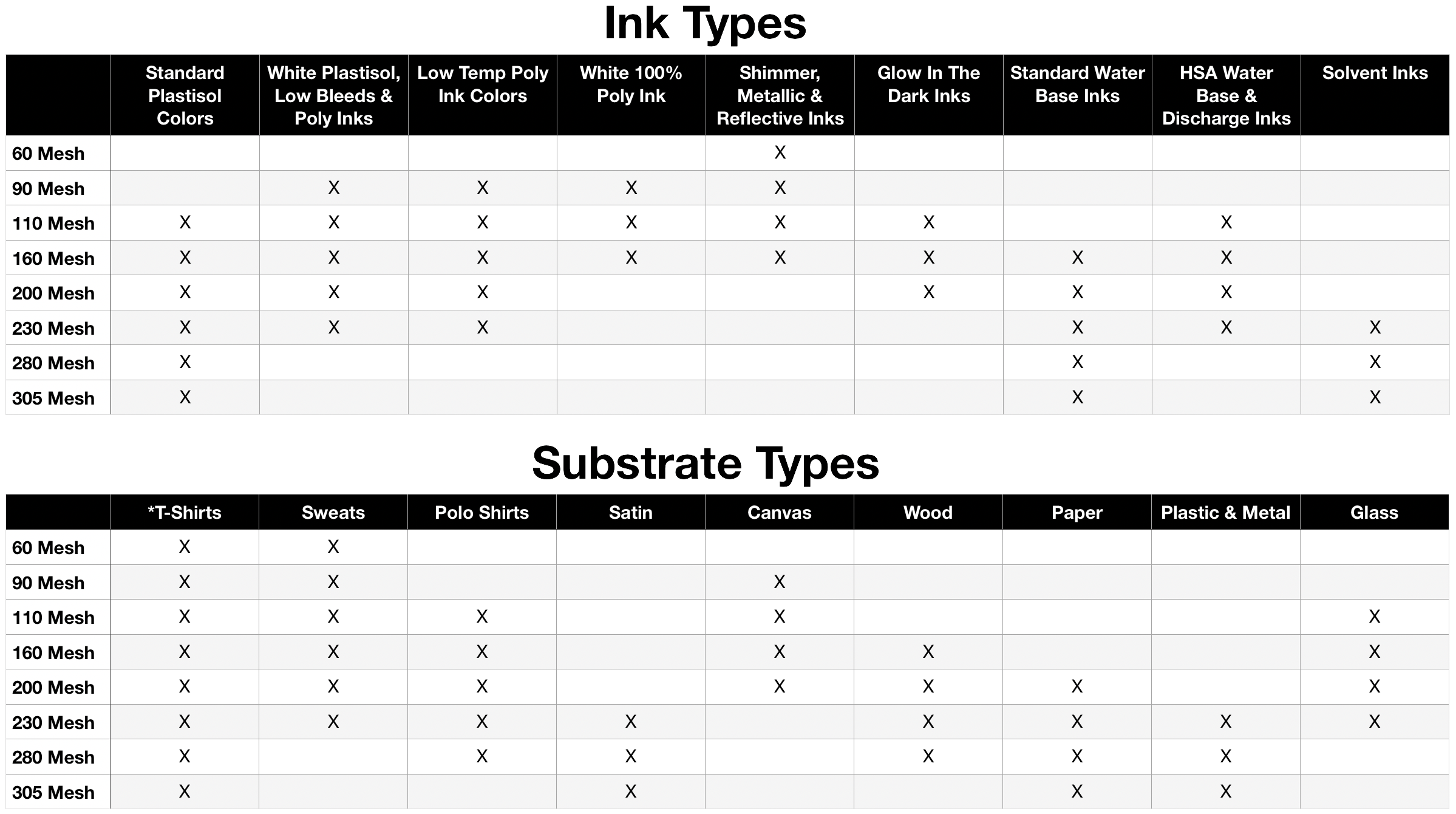

Beneath is a chart breaking downwardly common ink types and garment/substrate types to go y'all in the right mesh count ballpark.

*As yous tin run across, t-shirts love ink, and will yield good results with pretty much any mesh count every bit long as the ink passes through the mesh well. That being said, the tighter the knit of the t-shirt, the better the ink will print on top of the fabric allowing you lot to utilize a college mesh screen. If printing on a very plush combed cotton shirt, the ink will typically have trouble matting down the fibers and then you lot will typically desire to use a lower mesh count to lay downward more ink.

Continue In Heed

There is no "exact" mesh count to use in any situation, often times you can get very similar results using a range of different mesh counts. Screen printing is a craft, and experimentation is key to finding what works all-time for you.

Source: https://www.anthemprintingsf.com/Choosing-Your-Mesh-Count-s/277.htm

Posted by: lainezdrinnera76.blogspot.com

0 Response to "What Is The Minimum Line Width You Should Use On Screen Printing Spot Color On Tee Shirt"

Post a Comment